Vertical

Jacking-Up

From the 1990s, SCG started to develop and construct the technology of Vertical Jacking and was awarded “Shanghai Science and Technology Achievement Certificate”. We have finished more than 20 projects by vertical jacking in power plants and water plants.

The advantages of the technology are:

- Less affected by natural conditions such as tide, wind, and waves

- Simple equipment to avoid a large number of water operations

- Simple construction process and short construction period

- Lower costs compare to other process

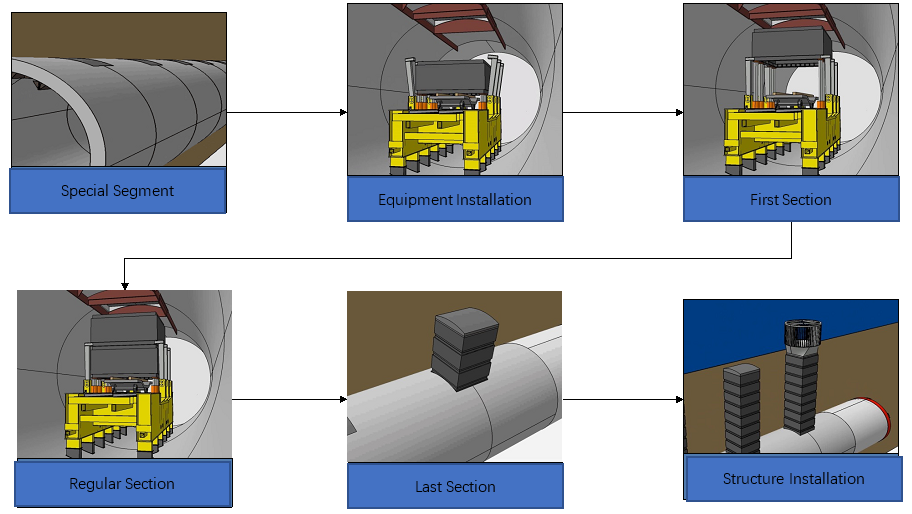

Technical Process:

Vertical jacking consists of pipe sections being jacked from the top of a previously installed tunnel up into soil and water above. Inside the newly built tunnel, the prefabricated pipe joints are connected to the tunnel lifting points and a jacking frame is placed beneath the vertical pipe sections (i.e. the cap). The cap and pipe joints are fastened with an internal bolt connection. After the pipe section (rectangular or circular) is in place, the cap and tunnel lining connection bolts are removed, and the pipe joint is pushed vertically by a hydraulic cylinder that results in the pipes being jacked into soil or water. After the completion of the jacking, the cap is removed from the soil or water and the project required manifold or diffuser sections is attached. Armoring and or concrete protection can be placed with a normal material to reform the drainage channel.

Vertical pipe jacking can be completed in tunnel or microtunnel pipe of 2.5-meter diameter or greater on pipe circular or rectangular sections.

Vertical

Jacking-Up

From the 1990s, SCG started to develop and construct the technology of Vertical Jacking and was awarded “Shanghai Science and Technology Achievement Certificate”. We have finished more than 20 projects by vertical jacking in power plants and water plants.

The advantages of the technology are:

- Less affected by natural conditions such as tide, wind, and waves

- Simple equipment to avoid a large number of water operations

- Simple construction process and short construction period

- Lower costs compare to other process

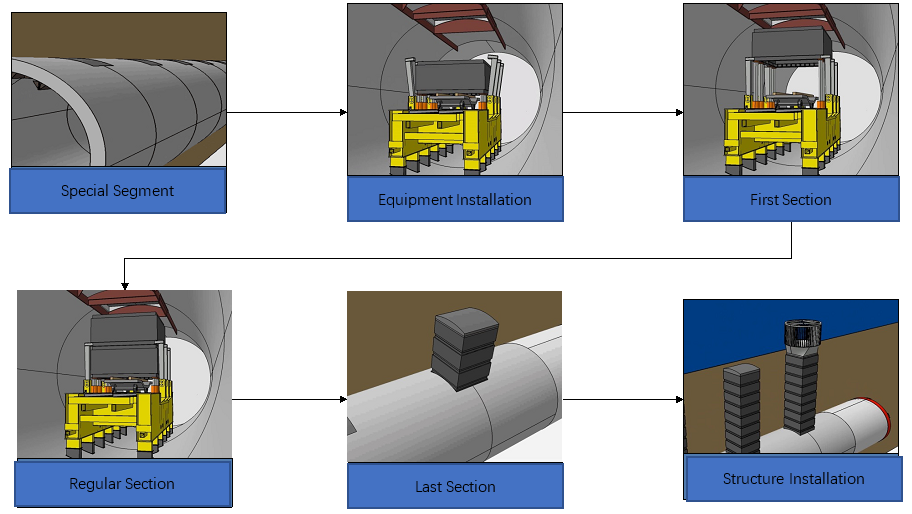

Technical Process:

Vertical jacking consists of pipe sections being jacked from the top of a previously installed tunnel up into soil and water above. Inside the newly built tunnel, the prefabricated pipe joints are connected to the tunnel lifting points and a jacking frame is placed beneath the vertical pipe sections (i.e. the cap). The cap and pipe joints are fastened with an internal bolt connection. After the pipe section (rectangular or circular) is in place, the cap and tunnel lining connection bolts are removed, and the pipe joint is pushed vertically by a hydraulic cylinder that results in the pipes being jacked into soil or water. After the completion of the jacking, the cap is removed from the soil or water and the project required manifold or diffuser sections is attached. Armoring and or concrete protection can be placed with a normal material to reform the drainage channel.

Vertical pipe jacking can be completed in tunnel or microtunnel pipe of 2.5-meter diameter or greater on pipe circular or rectangular sections.